What are TOPCon solar cells?

Photovoltaic (PV) module manufacturers are constantly working to find new, more advanced alternatives to improve the efficiency of solar panels. Efficiency can be improved through innovative cell manufacturing techniques, and now there are a few contenders in the solar photovoltaic market.

The latest module trends expect market growth to focus on HJT and TOPCon solar cells.

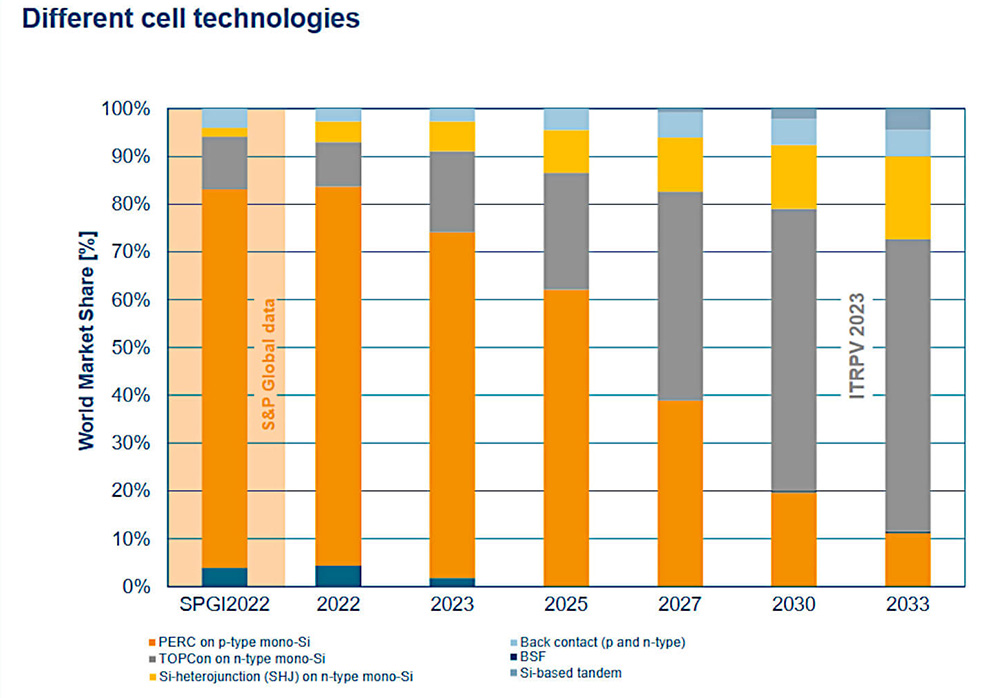

The 2022 report from the International Technology Roadmap for Photovoltaics (ITRPV) shows some of the expected trends over the next 10 years:

❖ PERC (passivated emitter rear contact) solar cell technology currently leads the market with a market share of approximately 75%. However, it is expected that the share of p-type monocrystalline PERC cells will drop to about 10% in the next 10 years.

❖ The market share of N-type TOPCon (tunnel oxide passivated contact) technology will increase from about 10% in 2022 to 60% in 2033, becoming the mainstream silicon wafer type. The largest increase is expected to begin in 2024.

❖ N-type HJT (heterojunction solar cells) is expected to increase from approximately 9% (2023) to over 25% in the next decade. The implementation of heterojunction cell technology still faces difficulties due to the high production costs of solar cells and the incompatibility of production lines with existing technologies.

P-type PERC and N-type TopCon

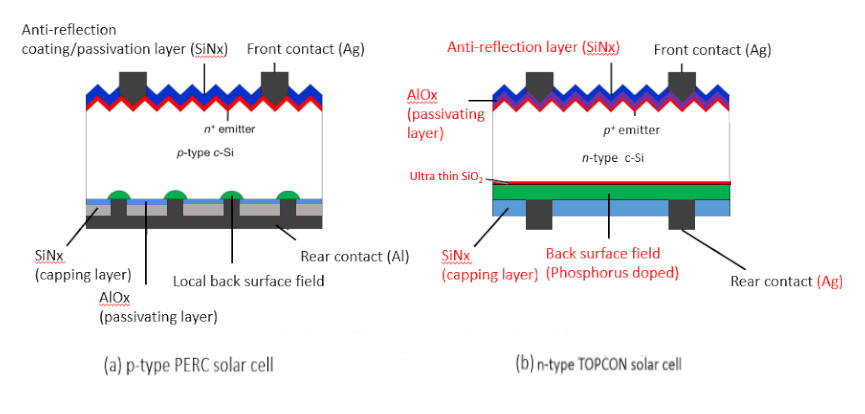

PERC technology is a cost-effective compromise between efficiency and large-scale production. But improving solar panel efficiency using this approach has been slow. The current efficiency of mainstream P-type modules is about 21.4%, and will increase to 22.75% in the next 10 years.

N-type TOPCon solar cells installed in photovoltaic modules look identical to PERC cells. Both P-type and N-type solar cells are made from silicon wafers. The difference between them is the way the wafers are doped with chemicals to increase the amount of electricity generated.

Simply put, P-type cells are doped with boron, while N-type cells are doped with phosphorus. In contrast, phosphorus degrades less than boron when exposed to oxygen. In addition, phosphorus doping can add free electrons to the wafer, thereby increasing efficiency.

Therefore, N-type based modules can achieve higher efficiency. It is estimated that efficiency, currently close to 22.5%, will increase to around 24% over the next 10 years.

The problem with the N-type manufacturing process is that it is still relatively expensive.

What are the advantages of TOPCon technology?

1. Manufacturing process

TOPCon modules can be manufactured using almost the same machines as P-type modules, which means that the use of TOPCon cells does not require a large investment by manufacturers.

2. Higher efficiency

According to the Fraunhofer ISE institute, efficiency can exceed 25%. The maximum theoretical efficiency of PERC cells is approximately 24%.

3. Reduce degradation rate

Compared to PERC panels, TOPCon modules have lower power decay during the first year and 30 years of PV panel life.

4. Lower temperature coefficient

TOPCon batteries have better resistance to extreme weather scenarios.

5. Double-sided rate

The bifacial coefficient of PERC PV modules averages about 70%, while the bifacial coefficient of TOPCon panels is as high as 85%. They capture more energy from the back than PERC bifacial modules, which is beneficial for ground-mounted utility projects. They are also more attractive from an aesthetic perspective than PERC solar panels.

6. Low light performance

TOPcon modules are more efficient in low-light conditions, extending power generation during the day and improving the performance of the installation over time.