Shingled Solar Cells

Shingled solar cells follow a similar process as solar roof shingles. They are made by cutting a full size solar cell into 6 equal strips. These cells strips are then assembled and stacked, like roof tiles, to form longer strings of up to 40 cells, depending on the size of the panels. This results in one-fifth (or one-sixth) the usual string voltage (V) but one-fifth (or one-sixth) the current (I). Therefore, by reducing the current flowing through the battery, the resistance is also reduced, and by reducing the resistance, the operating temperature is also reduced. And by lowering the operating temperature, the chance of hot spots forming can be reduced.

|

Advantages

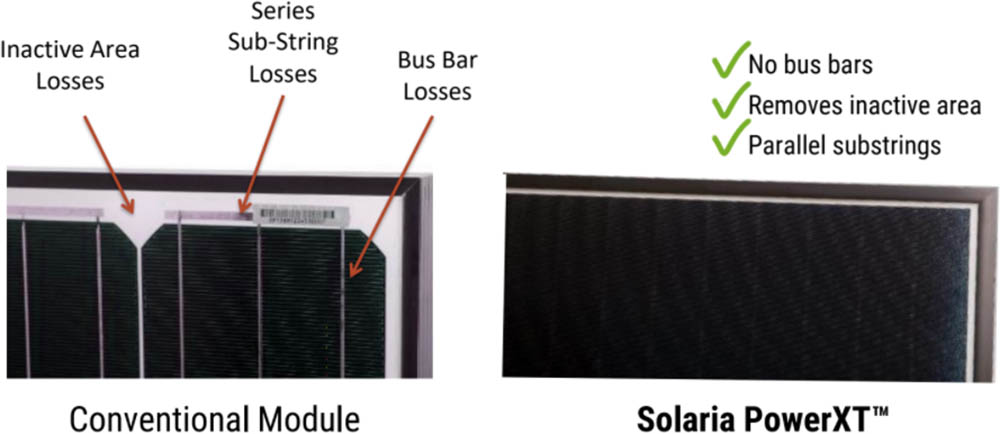

1. Non-busbar connection

In this arrangement, the cells are directly connected by physical contact, with no visible bus bars and straps required to hold the cells together. In the shingled configuration, nearly 30 meters of busbars and welded joints required by traditional solar panels are eliminated. This reduces the risk of bus failure.

|

2. Increased Power Harvesting

Spaces between cells are completely eliminated. This removes inactive areas of the panel, which can increase cell resistance and reduce performance. Thanks to more modules, almost 100% can be covered by solar cells, so more light can be collected per surface area.

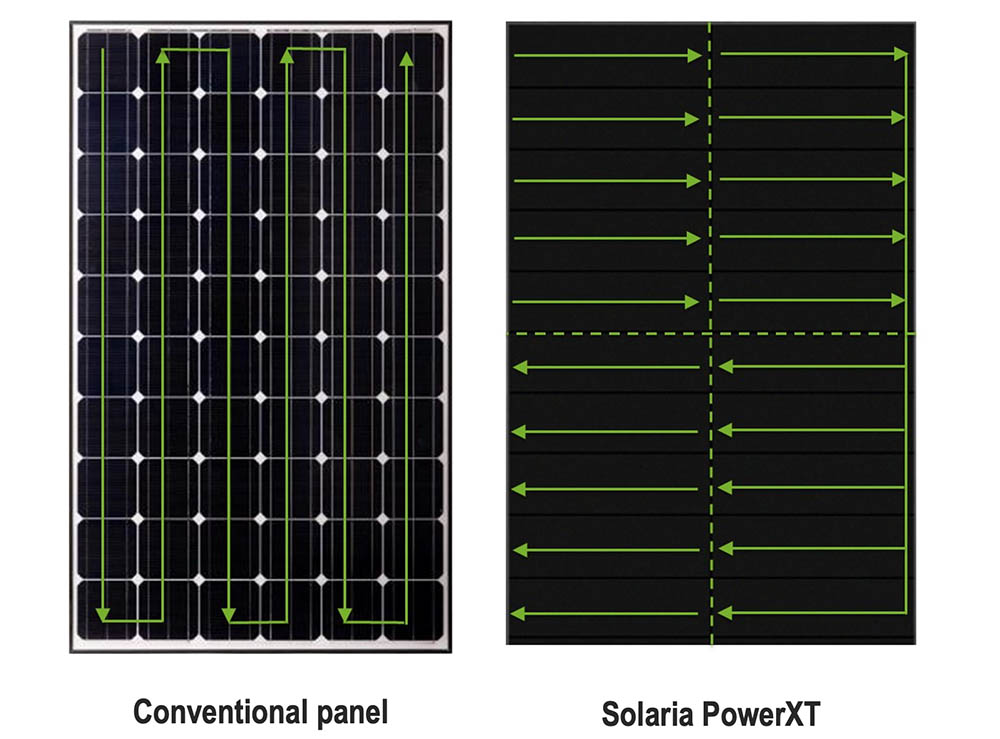

3. Parallel Cell connection

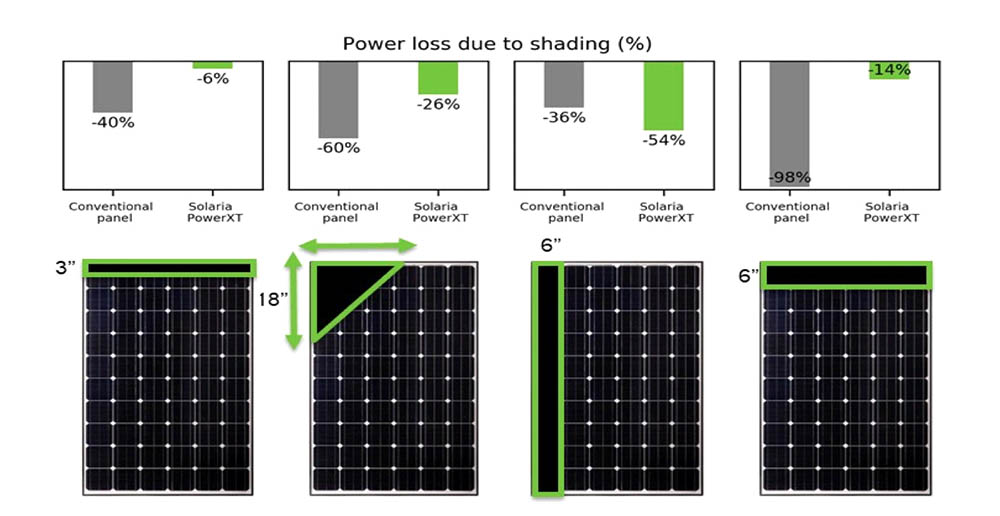

In a traditional solar panel, individual cells are connected in series. So when the cell is shaded, its performance degrades, and with it the performance of the entire solar panel. In a shingled configuration, cells can be wired in groups and configured in parallel, allowing cells to perform more independently of other cells.

4. The best solar panel aesthetics yet

The main attraction of the Ribbon Cell is its state-of-the-art aesthetics. Without any visible circuitry, their surfaces appear to be made of stained glass. How the solar panels blend aesthetically into the roof is an important consideration for manufacturers. Shingled solar panels are by far the most aesthetically pleasing, second only to IBC solar panels.

|

Shingled cell technology is compatible with more traditional silicon cell technologies such as full black, half-cut, PERC, HJT, etc. and can accommodate these configurations. At present, this emerging technology represents the highest limit of the development of traditional undoped crystalline silicon solar cells so far.