Hall Effect Sensors vs. Shunt Resistors Which is Better for Current Measurement?

When it comes to measuring electrical current, two of the most commonly used technologies are Hall Effect sensors and Shunt resistors. Both methods have their strengths and weaknesses, and the choice between them often depends on the specific requirements of your application. In this blog, we’ll explore the key differences, advantages, and limitations of Hall Effect sensors and shunt resistors to help you decide which is better for your current measurement needs.

How They Work

Shunt Resistors

A shunt resistor is a low-resistance precision resistor placed in series with the load. According to Ohm’s Law (V = IR), the voltage drop across the resistor is proportional to the current flowing through it. By measuring this voltage drop, you can calculate the current.

Hall Effect Sensors

Hall Effect sensors, on the other hand, use the **Hall Effect principle** to measure current. When a current-carrying conductor is placed in a magnetic field, a voltage (Hall voltage) is generated perpendicular to both the current and the magnetic field. This voltage is proportional to the current, allowing the sensor to measure it without direct electrical contact.

Key Differences and Comparison

| Feature | Shunt Resistors | Hall Effect Sensors |

| Isolation | No electrical isolation | Provides galvanic isolation |

| Power Loss | High (due to resistive heating) | Minimal (no direct contact with the circuit)|

|Accuracy | High (for low currents) | Slightly lower, but improving with technology|

| Size | Compact | Larger (requires additional components) |

| Temperature | High (resistance changes with | Moderate (affected by temperature and magnetic fields)|

Sensitivity temperature)

| Frequency Response | Limited (for high-frequency applications) | Better suited for high-frequency signals |

| Installation | Requires breaking the circuit | Non-invasive (clamp-on designs available) |

Advantages of Shunt Resistors

1. Cost-Effective: Shunt resistors are inexpensive and widely available.

2. High Accuracy: Ideal for low-current measurements where precision is critical.

3. Simple Design: Easy to integrate into existing circuits.

4. Wide Range: Can measure both AC and DC currents.

Advantages of Hall Effect Sensors

1. Galvanic Isolation: No direct electrical connection, reducing the risk of short circuits and improving safety.

2. Low Power Loss: No significant heat generation, making them ideal for high-current applications.

3. Non-Invasive: Can measure current without breaking the circuit, simplifying installation.

4. Versatility: Suitable for high-frequency and high-current applications, such as in automotive and industrial systems.

Limitations of Shunt Resistors

1. Heat Dissipation: High currents can cause significant power loss and heating, requiring thermal management.

2. No Isolation: Lack of electrical isolation can be a safety concern in high-voltage applications.

3. Limited Frequency Range: Not ideal for high-frequency current measurements.

Limitations of Hall Effect Sensors

1. Cost: More expensive than shunt resistors, especially for high-accuracy models.

2. Magnetic Interference: External magnetic fields can affect accuracy.

3. Temperature Sensitivity: Performance can vary with temperature changes.

4. Complexity: Requires additional circuitry for signal conditioning.

Which is Better for Your Application?

The choice between Hall Effect sensors and shunt resistors depends on your specific needs:

- Choose Shunt Resistors if

- You need a low-cost solution for low to moderate current measurements.

- High accuracy is critical, and power loss is not a concern.

- You are working with low-frequency signals.

- Choose Hall Effect Sensors if

- You need galvanic isolation for safety or high-voltage applications.

- You are measuring high currents or high-frequency signals.

- You want a non-invasive solution that doesn’t require breaking the circuit.

Conclusion

Both Hall Effect sensors and shunt resistors have their place in current measurement. Shunt resistors are a reliable, cost-effective choice for low-current, low-frequency applications, while Hall Effect sensors excel in high-current, high-frequency, and safety-critical environments. By understanding the strengths and limitations of each technology, you can make an informed decision that best suits your project’s requirements.

What’s your experience with these technologies? Share your thoughts in the comments below!

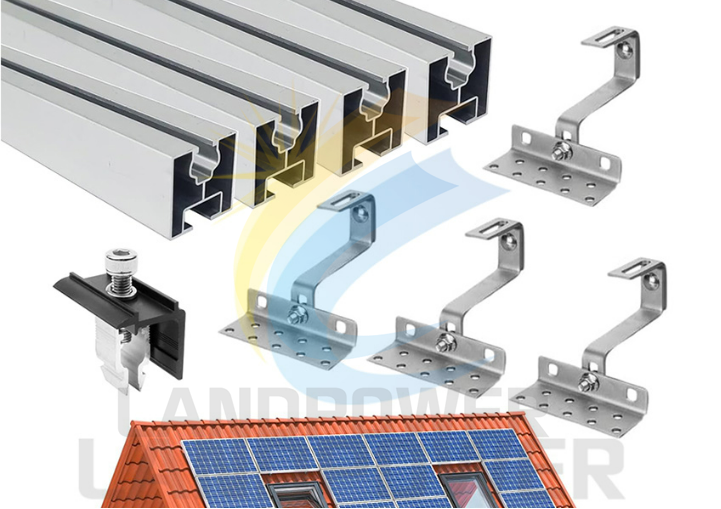

Corrugated Roof Clamp Solution - 1

Corrugated Roof Clamp Solution - 1