Flexible Solar Mounting Systems Breaking Tradition and Doubling Land Value!

In the field of PV power generation, flexible solar mounting systems are emerging as a new force, thanks to their unique design and functionality. Compared to traditional rigid mounting systems, flexible systems offer greater adaptability and versatility during installation and use, significantly expanding PV application possibilities and doubling land value.

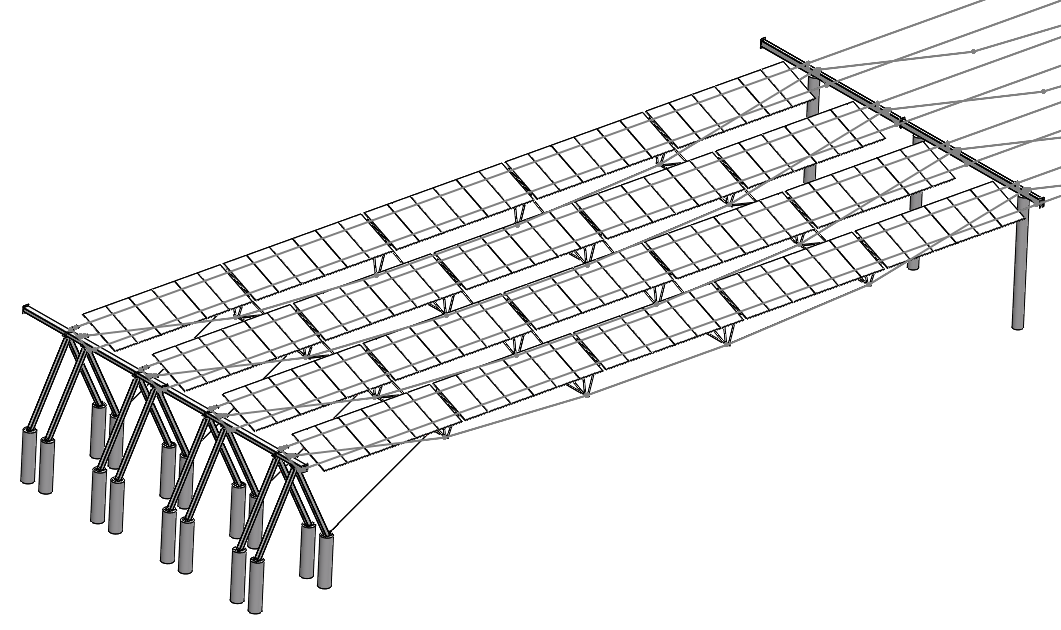

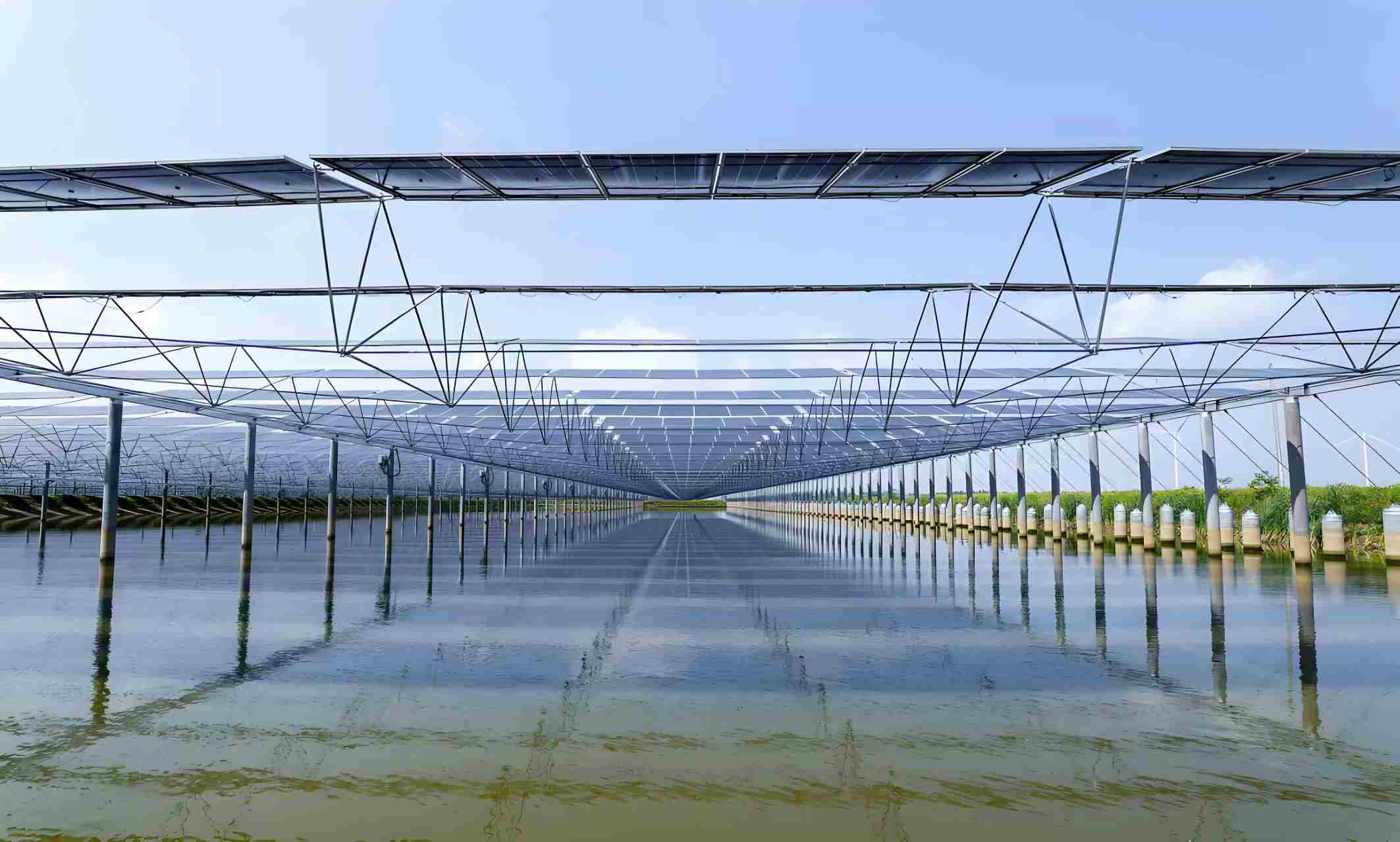

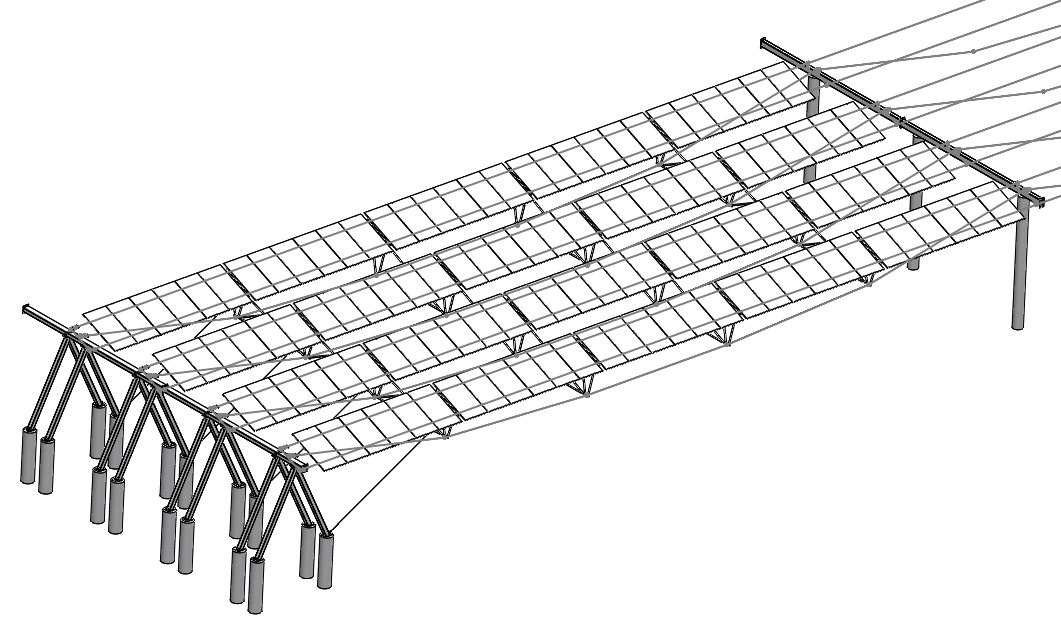

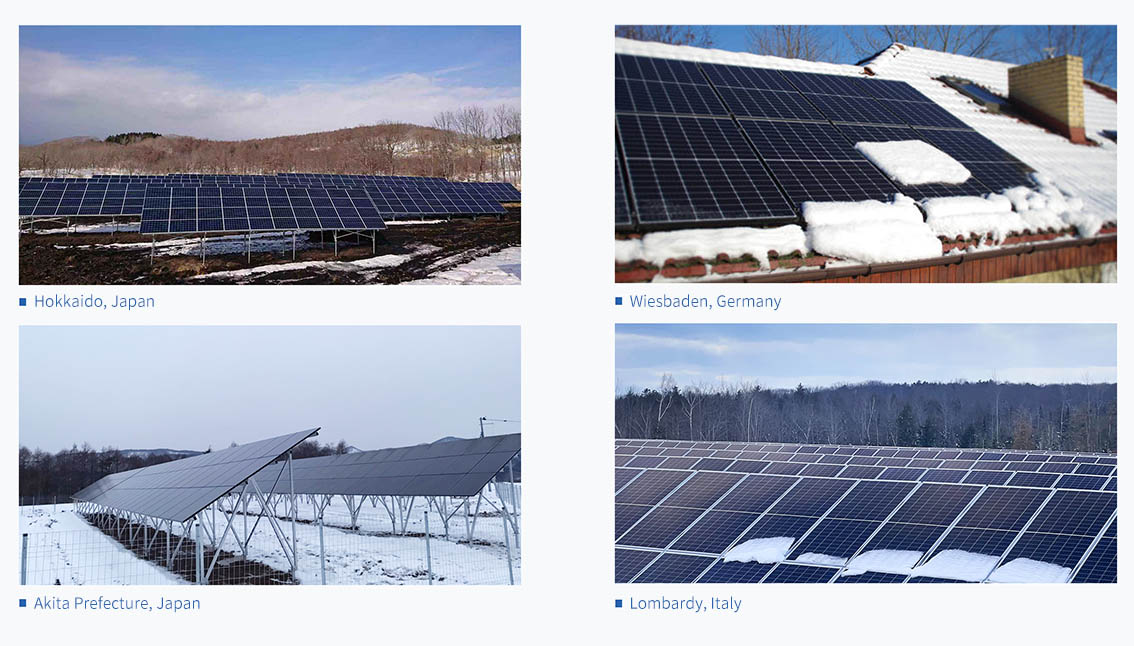

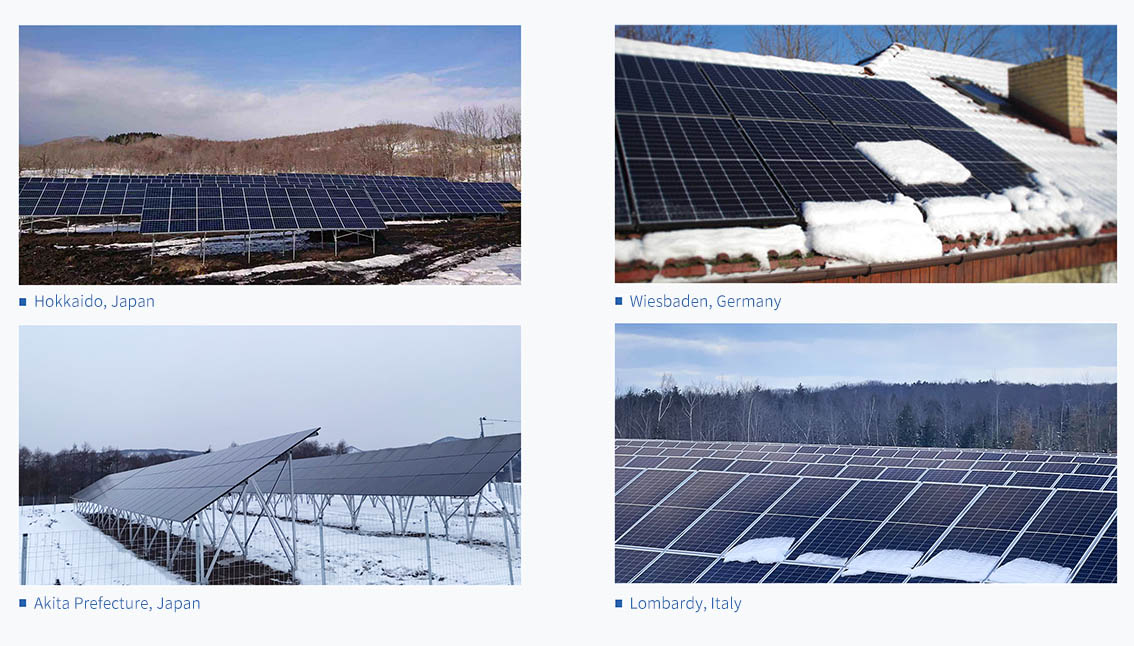

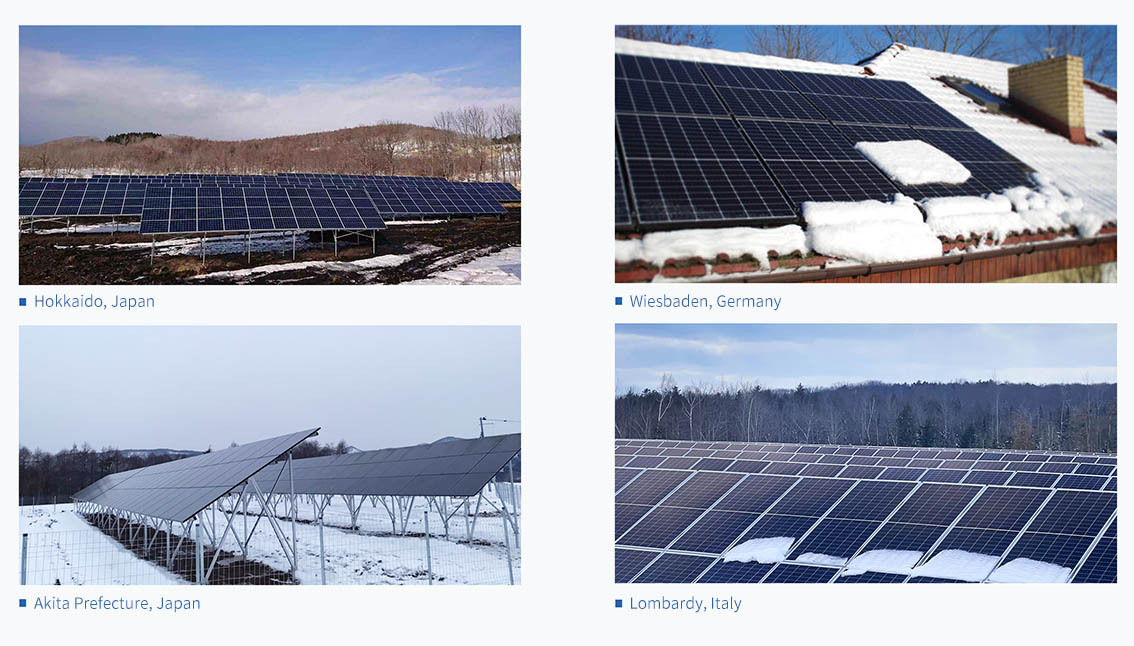

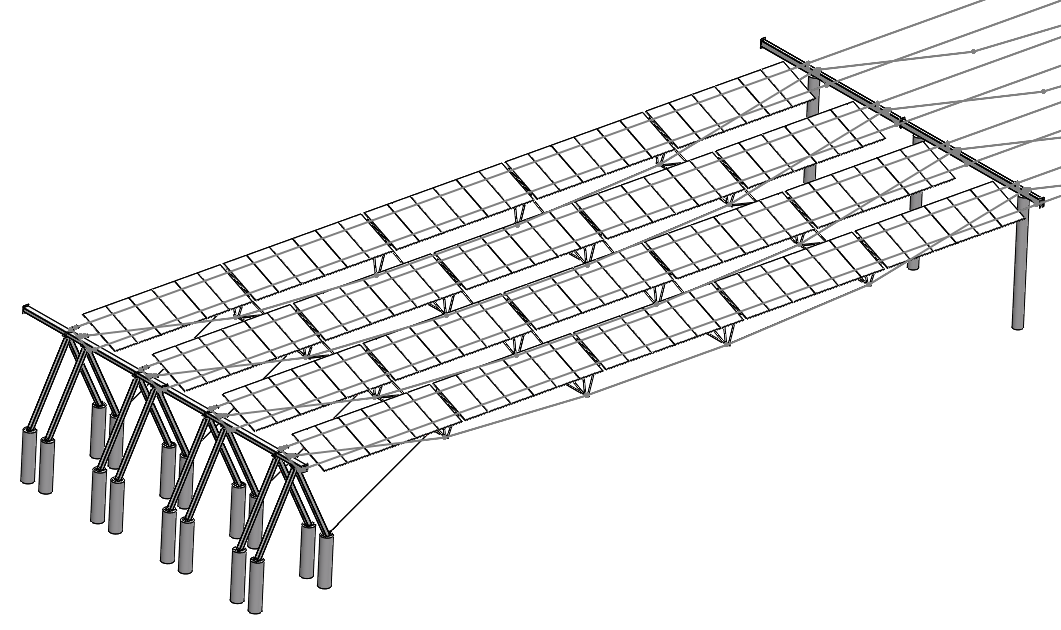

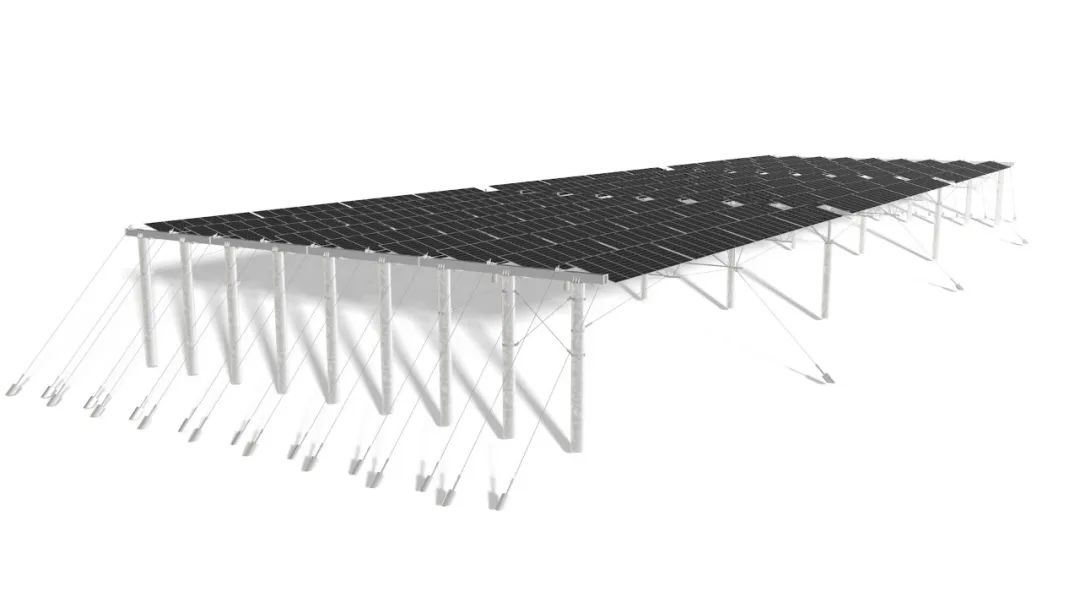

Firstly, flexible solar panel mounts feature higher ground clearance, larger spans, and reduced pile density. This design enables flexible systems to effortlessly meet various installation requirements in challenging terrains. Whether in wetlands, fish farms, or mountainous and barren landscapes, flexible mounts demonstrate remarkable flexibility, enabling wide-span coverage and a broad range of applications. This makes them highly promising in diverse environments.

Secondly, Through optimized design and flexible layouts, Flexible solar mounting systems allow more PV panels to be installed on limited land areas. This not only boosts energy output efficiency but also significantly improves land utilization rates. Furthermore, the high-density panel arrangement of flexible systems leaves ample space beneath the PV arrays, allowing for secondary land use. This effectively increases the economic value of the land.

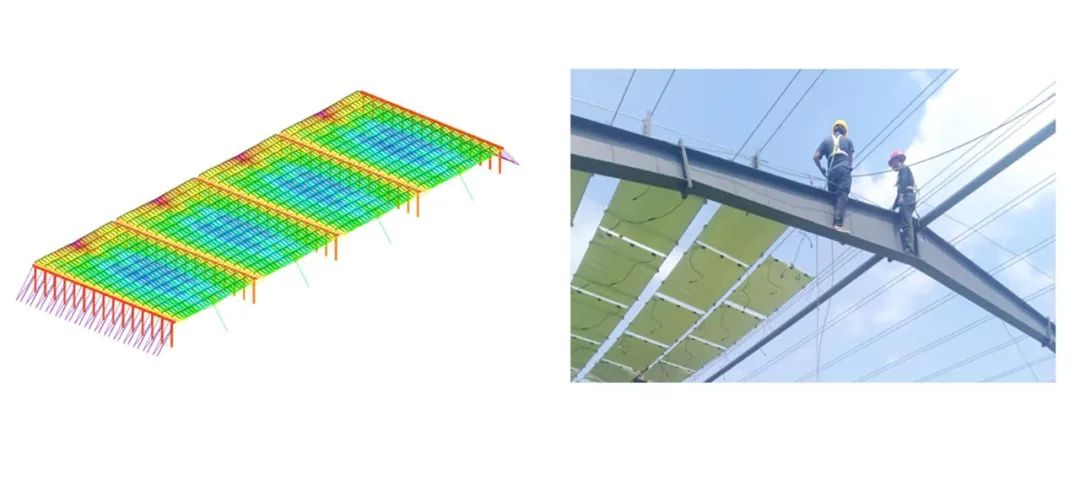

Notably, the pre-stressed tensioning solutions provided by flexible solar mounting systemgreatly reduce land leveling requirements, thereby lowering the overall investment cost of flexible mounting systems. This not only enhances the economic viability of PV projects but also ensures sustainable development. Flexible solar mounting systems not only overcome the limitations of traditional systems but also deliver significant economic and environmental benefits in real-world applications.

In summary, flexible solar mounting systems show immense potential in the PV sector. They enhance land utilization efficiency, increase energy output, and strongly support the sustainable development of PV projects. As technology continues to advance and applications expand, flexible solar mounting systems are expected to play a dominant role in the future of PV development.

For more information about flexible solar mounting systems, follow Huge Energy!

Advantages of Huge Energy Flexible Mounting System

Flexible solar mounting system offers a maximum ground clearance of up to 9 meters and a span of up to 50 meters. With its high clearance, wide span, and superior safety, it addresses challenges such as excessive land occupation, limited reuse potential, and high engineering costs associated with traditional mounting systems. This innovation promotes the widespread application of integrated "PV+" projects.

Huge Energy pre-stressed suspension system has passed CPP and RWDI wind tunnel testing certifications, ensuring effective resistance against typhoons of up to level 15. Its north-south stabilizing tie rods and wind-resistant cables enhance system stability, ensuring safety under extreme weather conditions.

Backed by a dedicated R&D team and a fully equipped laboratory, Huge Energy continuously improves product design and structural performance. The company has achieved comprehensive PV solutions with a track record of zero-risk incidents over the past decade.

Choosing Huge Energy means opting for efficient energy solutions and a commitment to sustainable development. With an expert team dedicated to every detail, We ensures your investment yields maximum returns!