The research and development of lithium batteries can be traced back to the 1970s. Early lithium batteries used materials such as lithium cobalt oxide as the positive electrode.

With the continuous advancement of technology, the types of lithium batteries have gradually increased. Lithium iron phosphate batteries were developed in later research. They have unique advantages in safety and cycle life, and have gradually become an important part of the new energy field.

1. The Difference In Chemical Composition and Principle

Lithium batteries generally use lithium metal or lithium alloy as the negative electrode material, and there are many types of positive electrode materials, such as lithium cobalt oxide (LiCoO₂), lithium manganese oxide (LiMn₂O₄), etc. Taking lithium cobalt oxide batteries as an example, during the charging and discharging process, lithium ions are intercalated and deintercalated between the positive and negative electrodes. When charging, lithium ions are removed from the positive electrode and embedded in the negative electrode through the electrolyte; the opposite is true when discharging.

The positive electrode material of lithium iron phosphate battery is lithium iron phosphate (LiFePO₄), and the negative electrode is usually graphite. During the charging and discharging process, lithium ions also move between the positive and negative electrodes. The crystal structure of lithium iron phosphate is stable, which makes the battery have good safety and stability during the charging and discharging process.

2. Energy Density Difference

Lithium battery: The energy density is relatively high. For example, the energy density of lithium cobalt oxide battery can reach about 150-200Wh/kg. This makes lithium batteries widely used in some electronic devices with high volume and weight requirements, such as smartphones, laptops, etc., and can provide devices with longer battery life.

Lithium iron phosphate battery: The energy density is generally between 100-150Wh/kg. Although the energy density is relatively low, in some application scenarios where the energy density requirements are not particularly extreme, such as electric buses, energy storage power stations, etc., its safety and cycle life are more prominent.

3. Safety Differences

Lithium battery: Some lithium batteries, such as lithium cobalt oxide batteries, may have safety problems such as thermal runaway under conditions of overcharging and high temperature. Because lithium cobalt oxide is structurally unstable at high temperatures, it is easy to release oxygen, which can cause dangerous situations such as combustion.

Lithium iron phosphate battery: It has excellent safety. It has good thermal stability and is not easy to decompose under high temperature conditions. The crystal structure of lithium iron phosphate can effectively prevent the disordered migration of lithium ions and reduce the risk of internal short circuits in the battery. Even in extreme cases, such as puncture and extrusion, lithium iron phosphate batteries are relatively unlikely to have serious accidents such as fire and explosion.

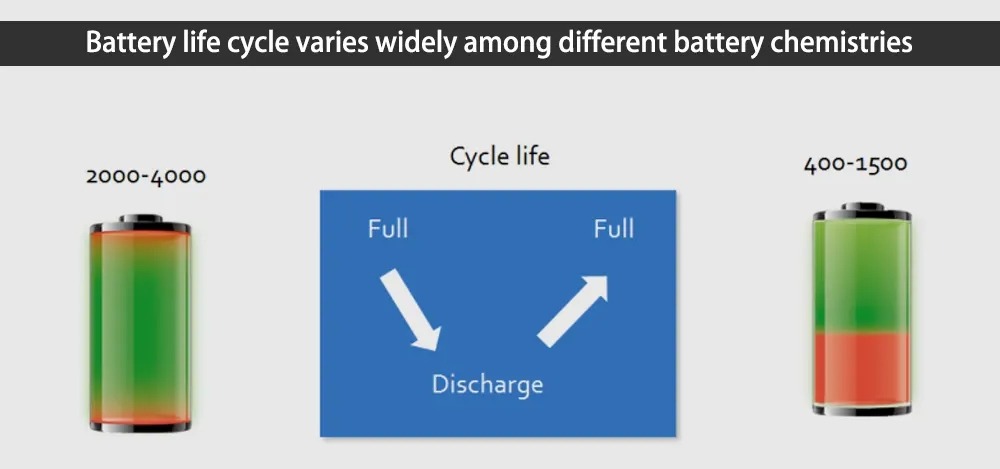

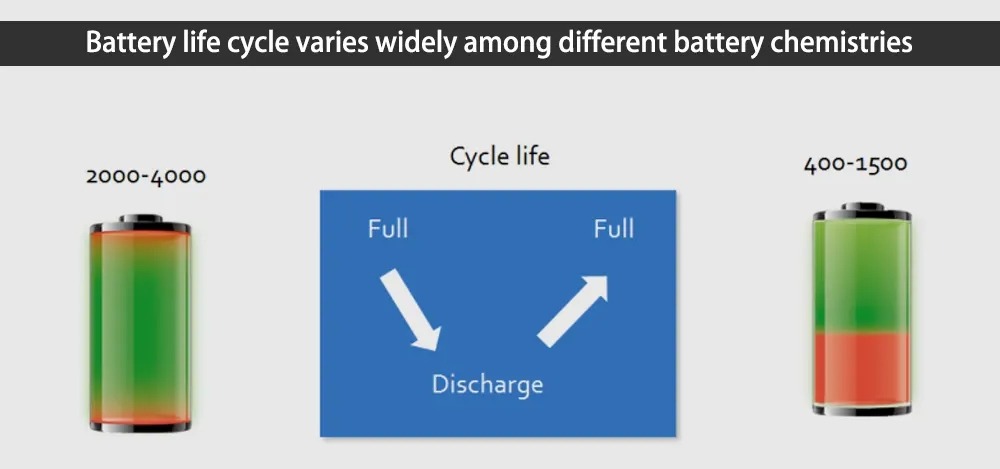

4. Cycle Life Difference

Lithium battery: The cycle life is generally around 500-1000 times, depending on the type of battery and the conditions of use. As the number of cycles increases, the battery capacity will gradually decay, affecting its performance.

Lithium iron phosphate battery: The cycle life is relatively long, reaching more than 2000 times or even higher. This makes it have great advantages in application scenarios that require long-term frequent charging and discharging, such as energy storage systems, which can reduce the frequency of battery replacement and reduce overall costs.

5. Charge and Discharge Performance

Lithium battery: The charging speed is relatively fast, and some lithium batteries can be fully charged in a shorter time. However, charging too quickly may have a certain impact on the battery life. In terms of discharge performance, it can meet the needs of most electronic devices and provide a relatively stable current output.

Lithium iron phosphate battery: The charging speed is relatively slow, which is one of its current shortcomings. However, in terms of discharge performance, lithium iron phosphate batteries have better large current discharge capabilities and are suitable for some applications that require instantaneous high power output, such as acceleration of electric vehicles.

6. Differences in Application

Lithium batteries are widely used in consumer electronics due to their high energy density and light weight, such as mobile phones, tablet computers, laptops, etc. At the same time, they are also used in some electric vehicles that require higher energy density, such as some of Tesla's early models that use lithium cobalt oxide batteries.

Lithium iron phosphate batteries are widely used in the field of new energy vehicles, especially in commercial vehicles such as electric buses and logistics vehicles. Their safety and long cycle life can meet the operational needs of commercial vehicles. In addition, they have also been widely used in energy storage fields such as energy storage power stations and solar street lights, providing a reliable solution for energy storage and utilization.

After a careful comparison between the two, there are obvious differences between lithium iron phosphate batteries and lithium batteries in terms of chemical composition, performance characteristics and application areas. They each have their own advantages and disadvantages, and play an important role in different scenarios.