N-type or P-type solar Panel?

What is the N-type and P-type Solar cell?

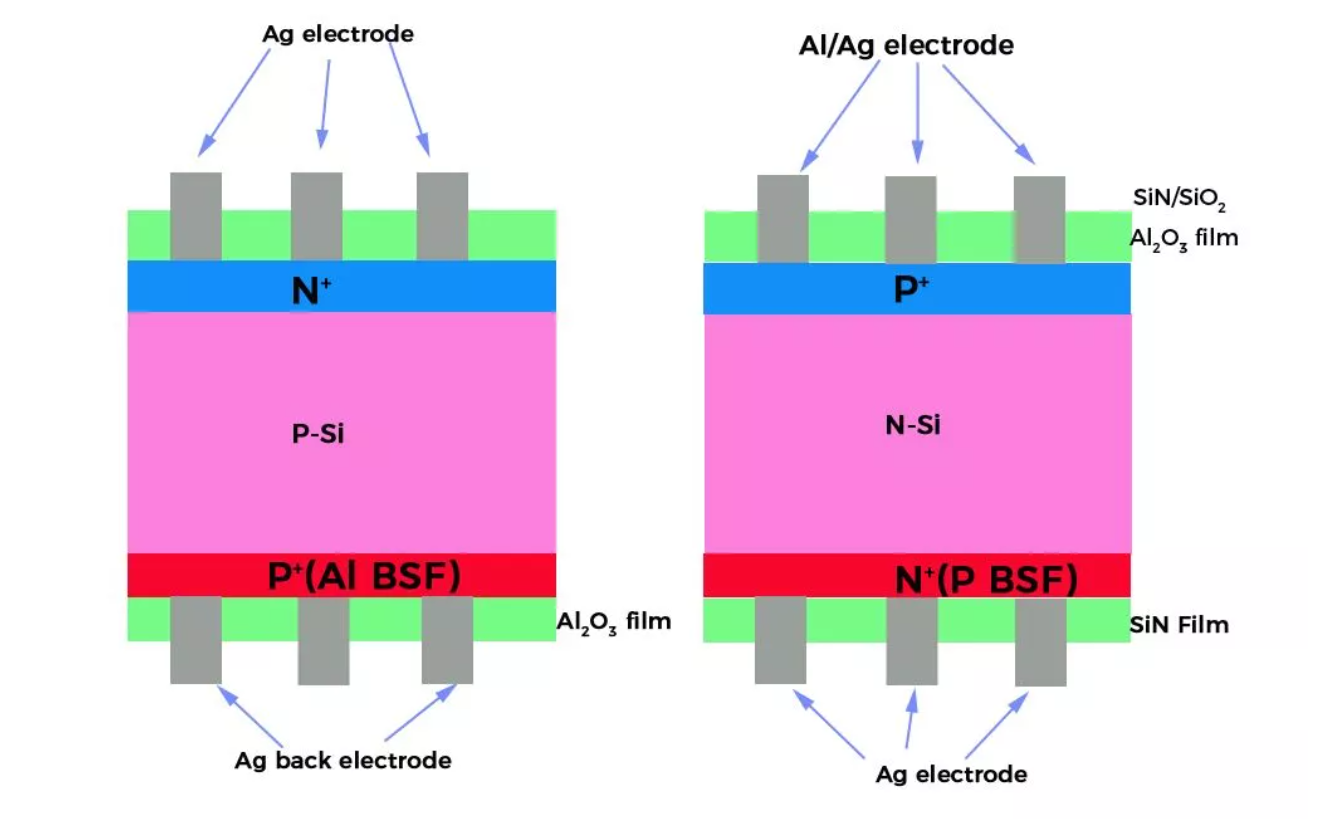

The average solar buyer probably is not paying attention to whether solar panels are made with p-type or n-type solar cells. But since you know there has N-type and N-type solar panel, you may start wondering what exactly difference between them and how they may affect solar panel buying in the future. A conventional crystalline silicon (c-Si) solar cell is a silicon wafer doped with various chemicals to encourage power production. The main difference between p-type and n-type solar cells is the number of electrons. A p-type cell usually dopes its silicon wafer with boron, which has one less electron than silicon (making the cell positively charged). An n-type cell is doped with phosphorus, which has one more electron than silicon (making the cell negatively charged).

Compared with P-type polycrystalline silicon wafers, the technical performance advantages of N-type monocrystalline silicon wafers are very firm:

- N-type cells/modules unaffected by boron-oxygen-related photodegradation;

- N-type substrates are more tolerant of common metallic impurities such as iron;

- N-type silicon wafer-based cells allow for bifacial cell designs that can absorb backside illumination to produce higher power;

It is also worth noting that N-type monocrystalline silicon wafers provide the substrate for a truly high-efficiency cell structure.

What is the future of N-type and P-type?

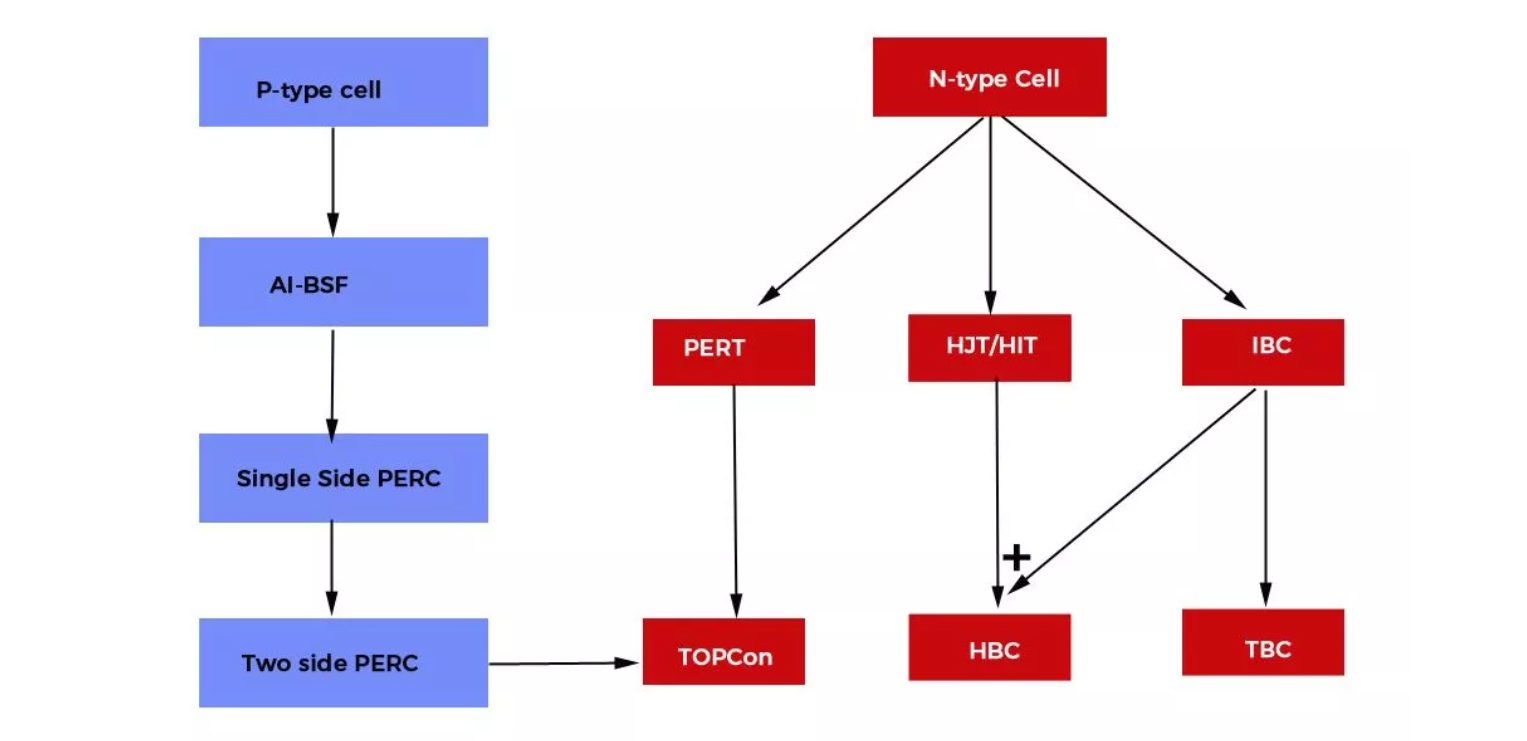

Looking ahead, it is more difficult to improve the efficiency of PERC cells,and the N-type technology with higher efficiency, lower attenuation rate and better low-light performance is recognized as the next generation photovoltaic cell technology. As far as the specific technical route is concerned, the three cell technologies of TOPCon (tunneling oxide passivation contact), HJT (intrinsic thin film heterojunction) and IBC (interdigital back contact) are widely sought after. Among them, TOPCon and HJT technology are the focus of industrial investment and market attention.

Considering the cost, TOPCon is one step ahead. It is reported that the theoretical maximum efficiency of TOPCon can reach 27.1% (single-sided) / 28.7% (double-sided). The advantage of TOPCon is that the production line is compatible with the existing PERC production line, which has also become the preferred iteration technology for large PERC capacity producers. With mass production, TOPCon companies claim that the cost of battery modules is expected to be equal to that of PERC within a year, and the cost of BOS will be significantly reduced.

According to the forecast of CPIA, in 2030, the market share of N-type batteries may reach about 56%, and the prospects are very broad.

Published on